Air mass meter

The Volkswagen T4 air flow meter (see Fig. 301, 303, 304) measures the amount of air entering the engine and, having processed this information, sends the corresponding electrical signal to the microprocessor module.

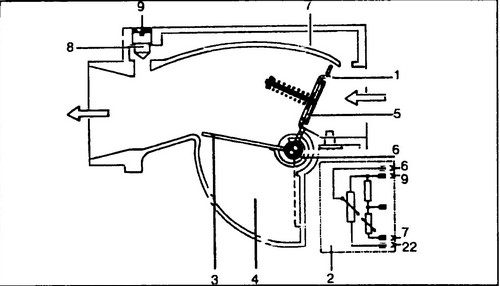

Rice. 303 Air mass meter device - typical design

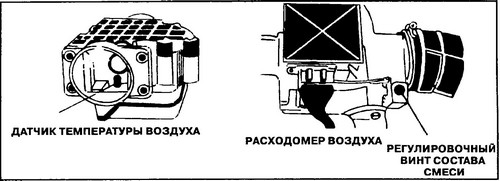

Rice. 304 Air temperature sensor (in the air flow meter)

Principle of operation

Volkswagen T4 air flow meters of the electromechanical principle of operation

The oncoming flow of incoming air causes the damper (1) to open (see Fig. 303).

The damper stops in a certain angular position, depending on the pressure (pressure) of the passing air and the resistance force of the return spring (6).

The signal is transmitted to a potentiometer (2) connected to the damper shaft. A compensation damper (3) of the same size is rigidly connected to the working damper (1).

Its task is to equalize the forces acting on the working damper in the event of sudden pressure drops. As a result, the system is protected from the influence of vibration on the measurement accuracy. The compensation damper reduces the influence of vibrations in the system due to the presence of a damping chamber (4).

The service valve is furthermore provided with a check valve (5) which protects the flow meter from damage in the event of knocking in the engine. A certain, small amount of air that cannot be measured is directed through the bypass channel (7) ("bypass" channel), the cross-sectional area of \u200b\u200bwhich can be changed with the adjusting screw (8), in this way it is possible to change the ratio of air to fuel in the mixture when idling .

The above adjustment allows you to adjust the composition of the fuel-air mixture if the concentration of CO in the exhaust gases at idle exceeds the permissible level.

The purpose of the adjusting screw (8) can be compared to the mixture adjustment screw in a carburetor.

In order to prevent accidental changes in the adjustment parameters, the screw must be fixed with a plug (9). Hot wire air mass meter

This type of air mass meter appeared later than the electromechanical devices described above.

The fundamental difference between these models is that there are no moving parts in the device, which increases the reliability of its operation. The principle of operation of the Volkswagen air flow meter

A wire heated by electric current is stretched across the air duct of the flow meter.

The air flow cools the wire, changing its resistance. The change in resistance is converted into a signal for the microprocessor module. The disadvantage of this design is the slow but constant fouling of the wire with slag from burnt dust particles, which leads to distortion of the measurement results.

As a possible way out of this situation, structures with a heated element of a tape (film) type later appeared.

Possible malfunctions caused by incorrect operation of the air mass meter.

- The engine does not start or starts with difficulty.

- The engine stalls immediately after starting.

- Unstable frequency XX.

- Poor engine dynamics (weak acceleration when pressing the "gas" pedal).

- Increased fuel consumption.

- The engine stalls after engaging any gear ("does not pull").

- Incorrect concentration of CO in the exhaust gases.

- The T4 engine has reduced power.

Motronic injection system . The principle of operation of the injection system .