Electric fuel pump

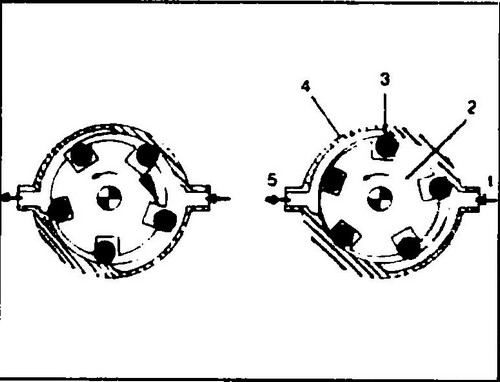

Roller-chamber fuel pump conveyor T4 , combined with a fuel level sensor with electric drive and excitation from permanent magnets (see Fig. 248), supplies fuel from the tank to the filter at a pressure of about 2.5 bar (0.25 MPa). The pump housing contains an eccentric disc rotor (2) (see Fig. 247).

Rice.

247 The principle of operation of the Volkswagen T4 fuel pump 1 - fuel supply, 2 - disc rotor, 3 - roller, 4 - roller track, 5 - fuel outlet

In the cuts made along the contour of the rotor, metal rollers (3) are located, moving outward under the action of centrifugal force and acting as a membrane for pumps of a classical design.

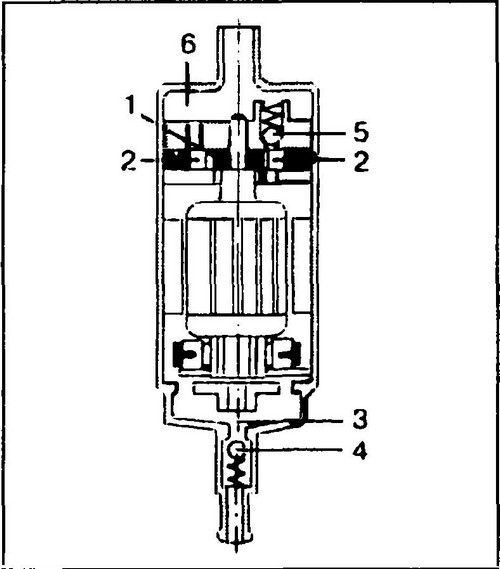

Fuel enters the empty chambers and is compressed in the fuel lines (see Fig. 248). The non-return valve (4) prevents fuel from returning to the fuel tank when the engine is off.

Rice.

248 Fuel pump device Conveyor - typical design 1 - eccentric disk, 2 - rollers, 3 - fuel delivery chamber, 4, 5 - valves, 6 - fuel intake chamber from the tank

If the pressure is more than 4 bar, a special valve (5) circulates the fuel in the chamber (6).

The control relay turns on the fuel pump power system immediately after the ignition is turned on.

If the engine is accidentally stalled and the ignition switch is in the "drive" position, the power supply to the pump will immediately stop.

Possible malfunctions caused by incorrect operation of the electric fuel pump:

- The engine does not start or starts with difficulty.

- Unstable idle speed.

- The engine stalls regardless of the transmission gear.

- Reduced engine power.

Advantages and disadvantages the Digifant system. Volkswagen T4 engine malfunctions .