Cylinder block

Before repair, thoroughly clean all cavities and valves of the block from scale, resinous deposits, etc.

Blow them out with compressed air. ♦ To determine the piston clearances in the cylinders, measure the piston diameters (see fig. 106) and write them down, and then measure the cylinder bore diameters as follows

: Fig. 104).

♦ Measure the cylinder diameter at the middle of the piston stroke.

Both of the above measurements are made in the direction along the axis of the block, and then again in the transverse direction at the same levels (see the measurement scheme in Fig. 105). All cylinders are subject to regrinding to the nearest repair size, if at least in one place the measured diameter differs from the required one by more than 0.08 mm. There are pistons of two repair sizes. the Volkswagen T4 cylinder head . Check the seating surface of the block head in the longitudinal, transverse and diagonal directions. The maximum allowable gap is 0.1 mm.

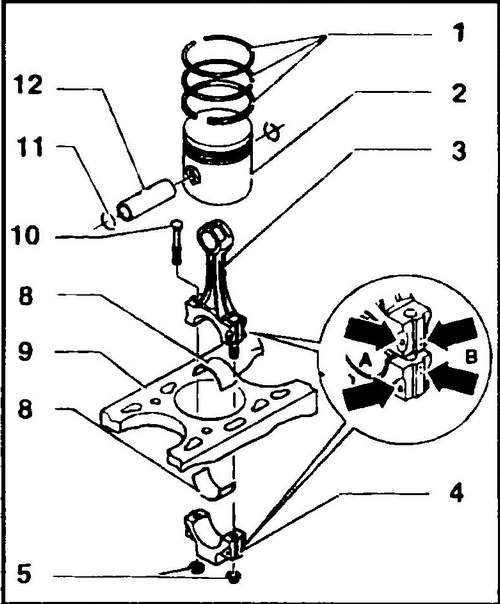

Rice.

110 Piston and connecting rod assembly The letters show the places where the connecting rod and cap are marked (A), as well as the location of the lugs (B). The tides should be directed towards the belt pulley 1 - piston rings, 2 - piston, 3 - connecting rod, 4 - cap of the lower head of the connecting rod, 5 - connecting rod nut, 6 - connecting rod bolt, 8 - connecting rod liner, 9 - cylinder head, 10 - bolt, 11 - piston pin circlip, 12 - piston pin