Gas distribution system

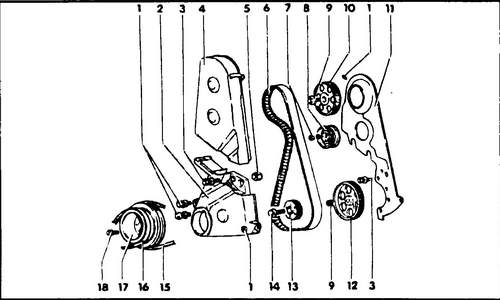

The drive of the camshaft placed in the head of the Volkswagen Transporter T4 is carried out using a toothed belt laid on the toothed pulleys of the shafts: crankshaft, distribution and intermediate. The drive device is shown in fig. 123. The figure shows that the toothed belt is completely closed from both external and internal influences. The crankshaft toothed pulley has a protrusion that fits into the groove of the crankshaft. Under normal conditions, the service life of the drive belt is about 100,000 km.

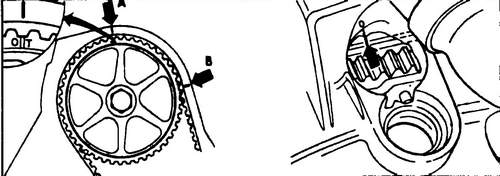

Rice. 122 TDC marks - engine 2.0

Rice.

123 Camshaft drive device - models up to 1996 1 - bolt with washer, 10Nm, 2 - lower toothed belt guard, 3 - bolt, 20Nm, 4 - upper toothed belt guard, 5 - bushing, 6 - toothed belt, 7 - nut, 45Nm, 8 - tensioner pulley, 9 - bolt, 80Nm, 10 - camshaft pulley, 11 - toothed belt rear guard, 12 - countershaft pulley, 13 - crankshaft pulley, 14 - crankshaft pulley bolt, 90Nm+quarter turn, 15 - alternator drive belt, 16 - power steering pump drive belt , 17 - damper, 18 - V-pulley bolt

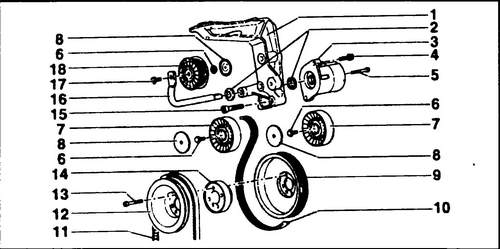

Rice.

124 Camshaft drive device - production models since 1996 1 - bracket, 2 - o-rings, 3 - tensioner, 4 - bolt, 20 Nm, 5 - bolt, 10 Nm, 6 - bolt, 20 Nm, 7 - guide roller, 8 - plug , 9 - V-ribbed belt pulley, 10 - V-ribbed belt, 11 - V-belt, 13 - V-belt pulley, 13 - bolt, with shoulder - 25 Nm; without collar - 80 Nm, 14 - bushing, 15 - bolt, 40 Nm, 16 - tensioner roller lever, 17 - mounting bolt, 18 - roller

The tension of the toothed belt is carried out using a tensioner roller.

Replacing the flywheel on T4 . Engine T4 Transporter.