Hydraulic System Maintenance

Filling the hydraulic steering system with fluid

After removal and installation of the steering gear, the Transporter T4 must be filled with hydraulic fluid “G 002 000" and then bled. Fluid drained during removal is not recommended to be used again.

The filter must always be replaced if the steering gear has been replaced or if the hydraulic fluid has been replaced The following order of operations must be followed:

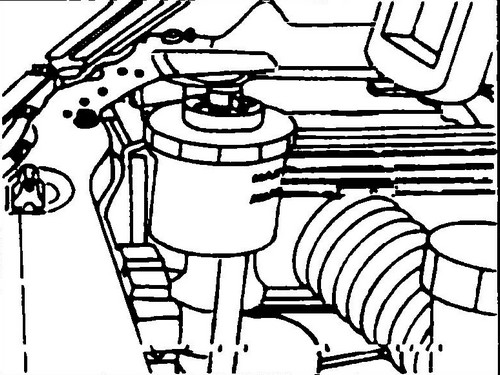

♦ Fill the system reservoir up to the upper edge Fig. 416 shows this reservoir with clearly visible marks “MAX” and “MIN”.

Rice. 416 Hydraulic fluid reservoir power steering system

♦ Start the engine briefly several times and turn it off after each start.

This will ensure that the entire system is filled with liquid. ♦ During start-up, the fluid level in the reservoir drops rapidly and therefore it is necessary to constantly top up the fluid. It is unacceptable for the tank to be completely empty, as this will allow air to enter the system.

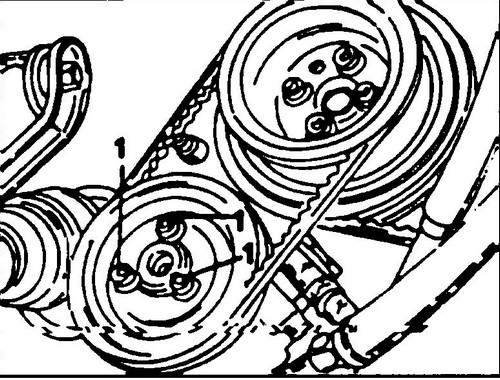

Rice. 417 Three bolts (1) of the drive pulley must be unscrewed to get to the shims

Rice. 418 Adjusting the tension of the V-belt of the power steering pump in a five-cylinder engine

If the fluid level stops dropping and stabilizes, the system is completely filled with hydraulic fluid.

Bleeding of hydraulic system of the hydraulic booster

The device of hydraulic system of the hydraulic booster is shown on fig. 419, 420.

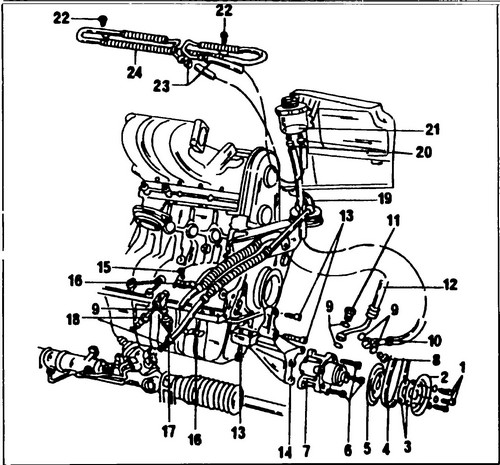

Rice.

419 Power steering pump location - 1.9 and 2.0 engines 1, 6, 13 - bolt, 20 Nm, 2 - front half of the drive pulley, 3 - shim, 4 - V-belt 10x655mm, 5 - rear half of the drive pulley, 7 - power steering pump, 8 - hollow bolt, 40 Nm, 9 - sealing ring, 10, 19 - return pipe, 11 - union nut, 30 Nm, 12 - supply hose, 14 - pump bracket, 15 - bolt, 16 - pressure sensor , 15 Nm (only in a gasoline engine), 18 - adapter 30 Nm, 20 - clip, 21 - hydraulic fluid reservoir, 22 - bolt, 8 Nm, 23 - clamp clamp, 24 - coolant radiator mounted on the cross beam

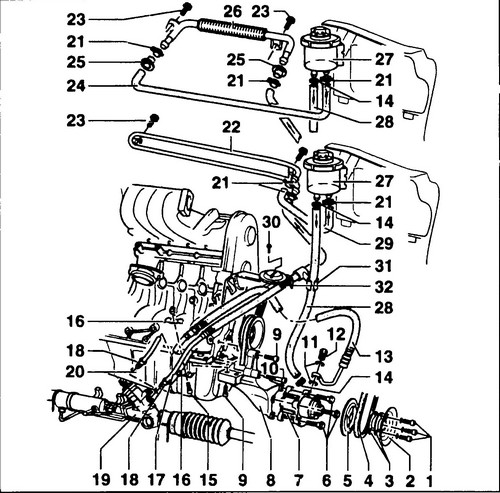

Rice.

420 Power steering - engines 1.9, 2.0 and 2.8 1, 6, 9, 10 - bolts, 20 Nm, 2, 5 - V-belt pulley disks, 3 - belt tension adjustment washers, 4 - power steering pump drive V-belt, 7 - pump hydraulic booster, 8 - bracket, 11,20 - sealing rings, 12 - hollow bolt, 40Nm, 13 - hydraulic fluid supply hose, 14, 21 - clamps, 15, 23, 30 - bolts, 10Nm, 16 - bracket, 17 - return pipeline, 18 - union nut, 30Nm, 19 - steering gear with hydraulic system, 22, 26 - hydraulic fluid cooling section, 24 - return hose, 25 - adapter, 27 - compensation tank 28, 29 - hydraulic fluid return hoses, 31 - retainer , 32 - bracket

If the fluid level in the tank does not drop after starting the engine, you can leave the Transporter T4 .

Turn the steering wheel quickly (several times) to one side and the other until it stops.

In extreme positions, do not pull the wheels to the stop with great force, so as not to cause too much pressure in the hydraulic system. It is sufficient if the piston only reaches the stops on both sides. ♦ Keep an eye on the fluid level in the reservoir.

If it drops, you must immediately add fluid, since the level must always be at the “MAX” mark in the tank. When turning the steering wheel from lock to lock, no air bubbles should appear in the reservoir. A constant decrease in the liquid level indicates a leak in the hydraulic system! Checking the tightness of the hydraulic system

In order to determine the location of the leak, you must perform the following steps.

♦ Ask an assistant to turn the steering wheel from lock to lock, holding it briefly in the extreme positions.

Thus, the greatest pressure is created in the system and then leaky places are easy to detect by passing hydraulic fluid. ♦ From the bottom of the vehicle, inspect the area around

the drive gear (rotary distributor). Remove the rubber boots from the rack and check the ends of the rack (O-rings). Check power steering pump and hose connections.