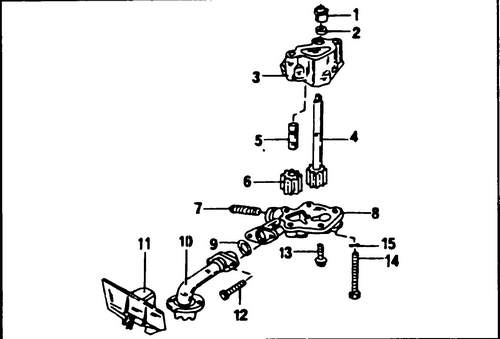

Oil pump repair

When disassembling the oil pump Transporter T4, use fig. 131.

Rice.

131 Oil pump device 1 - ignition distributor drive clamp, 2 - oil pump drive clamp, 3 - oil pump housing, 4 - drive gear shaft, 5 - driven gear shaft, 6 - driven gear, 7 - spring, 8 - pump cover, 9 - sealing ring, 10 - pump feed pipe, 11 - oil guide, 12 - bolt, 13 - M6x22mm bolt, 14 - M8x90 mm bolt, 15 - spring washer.

♦ Remove the two short screws from the pump cover.

♦ Remove the pump cover together with the delivery tube.

♦ Remove the drive shaft with gear and driven wheel from the pump housing.

♦ Remove both bolts securing the feed pipe to the T4 oil pump .

♦ Check the condition and wear of the pump casing.

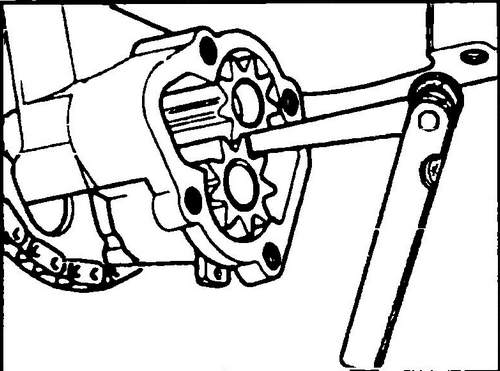

Check the condition of the gear bearings. When they wear out, the pressure of the engine oil decreases. In such cases, the pump housing assembly must be replaced. ♦ Check gear wear by inserting a feeler gauge between the teeth as shown in fig. 132. The gap should be in the range of 0.05-0.20 mm. If it is larger, replace both gears.

Rice. 132 Measuring the gap between the gears of the oil pump

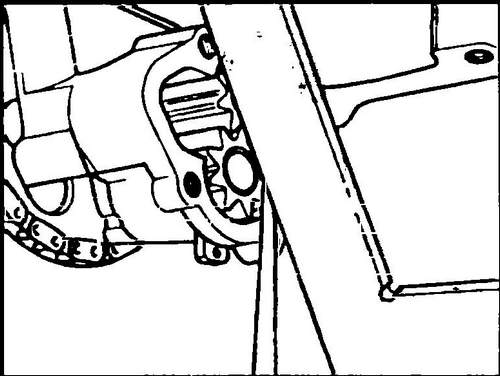

The axial clearance of the gears should be 0.06-0.15 mm. In order to measure it, it is necessary to attach a steel square or ruler to the surface of the pump housing, as shown in Fig. 133 and measure the gap between the square (ruler) and the end surfaces of the gears.

Rice. 133 Measuring the axial clearance of the gears of the oil pump

♦ Always replace both gears at the same time if you find wear or damage to the teeth.

♦ During assembly, pay attention to the cleanliness of the seating surfaces of both body parts. Coat all parts with engine oil before installation. Before installing the pump in the Volkswagen Transporter engine, check whether the gears rotate smoothly.