Removal and installation of the oil pump T4

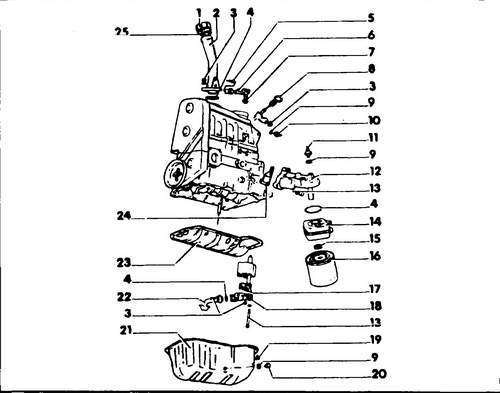

The method of mounting the oil pump Conveyor T4 on the engine block is shown in fig. 130.

Rice.

130 T4 oil pump location 1 - filler cap, 2 - filler neck, 3 - nut, 10Nm, 4, 7, 9 - o-rings, 5 - crankcase ventilation system hose (to intake pipe), 6 - ventilation system pressure reducing valve, 8 - oil dipstick, 10 - oil pressure sensor, 0.3 Bar (0.03 MPa), 25 Nm, 11 - oil pressure sensor, 1.8 Bar (0.18 MPa), 25 Nm, 12 - oil filter bracket, 13 - bolt, 20 Nm, 14 - oil cooler, 15 - nut, 25 Nm, 16 - oil filter, 17 - oil pump gears, 18 - oil pump cover with pressure reducing valve, 19 - bolt, 20 Nm, 20 - oil drain plug, 30 Nm, 21 - oil sump, 22 - oil pump suction pipe 23 - oil level damper in the crankcase, 24, 25 - gaskets

♦ Remove the oil sump as described above.

♦ Remove the bolts securing the T4 oil pump.

♦ Pull the pump down until the pump drive shaft is completely disengaged, then remove the pump from the engine block.

♦ Remove the ignition distributor, otherwise the pump cannot be installed. The pump is installed in the reverse order. The pump is attached without a gasket, directly to the motor housing. Tighten the fastening bolts to a torque of 20 Nm. Before installing the ignition distributor, turn the pump shaft so that the collar cavity is parallel to the longitudinal axis of the engine. Only then can the ignition distributor or the gland bush be upset, adjust the ignition.