Engine Oil Pressure Check

Oil pressure - check

Engine oil pressure in the engine lubrication system Transporter T4 is one of the most important parameters.

With a noticeable drop in pressure, you cannot continue to operate the car, but you must definitely find the cause of the oil drop and eliminate it. The most common causes are: - low engine oil level due to system leakage (due to a drop in the level in the crankcase),

- failure of the oil pressure sensor or indicator (sometimes happens due to severe frosts),

- wiring damage,

- general engine wear, with a sharp drop in oil pressure T4 - turning the main or connecting rod bearing,

- when using domestic engine oil at low air temperatures, damage to the pressure sensor or process plugs may occur due to a sharp increase in oil pressure at a particular point.

Checking the pressure consists in determining the real pressure of engine oil in the system with a known-good pressure gauge with an adapter screwed in instead of the standard oil pressure sensor.

VW T4 gasoline engines use two engine oil pressure sensors - the second sensor is connected to the warning horn. If the oil pressure drops below 0.3 bar (0.03 MPa), then the first oil pressure sensor closes the electrical circuit of the warning light on the instrument panel. If the pressure drops below 1.8 Bar (0.18 MPa), and the engine speed is greater than 2150 rpm, then the contact of the second 1.8 Bar sensor will not open, the control lamp on the instrument panel will light up and a warning sound will turn on. Checking the oil pressure T4

♦ Check the engine oil level and top up if necessary.

♦ Switch on the ignition, the oil pressure warning light should be on.

♦ Start the engine.

The oil pressure indicator light should go out. ♦ Remove the end of the electric wire from the pressure sensor 0.3 bar (sensor in brown insulation) and short it to the vehicle ground, the control lamp should light up.

♦ Replace the wire end removed from the pressure sensor.

♦ Disconnect the electrical wire from the 1.8 bar sensor (sensor in white insulation).

♦ Keep the engine speed above 2500 rpm for at least 1 second.

The oil pressure indicator light should come on and the buzzer should sound. Pressure gauges are used to measure pressure.

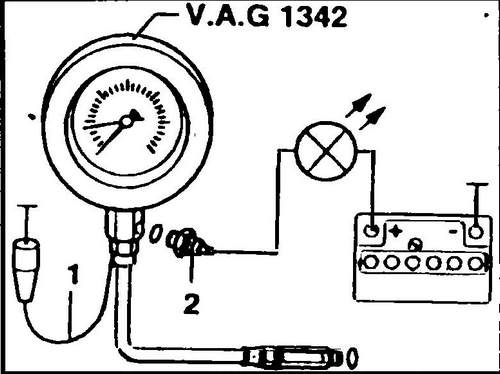

The pressure is measured in the following way: ♦ Unscrew the 0.3 bar pressure sensor from the block head and screw it into a special pressure gauge (see fig. 134).

Rice.

134 Scheme for checking oil pressure Conveyor T4 1 - brown wire, 2 - blue wire

♦ Connect the tip of the blue electric wire (2) to the sensor.

♦ Screw the pressure gauge adapter into the block head instead of the sensor.

♦ Connect the test lamp to the battery and the blue wire as shown in fig.

134. ♦ Connect the wire (1) to ground.

♦ Switch on the ignition.

♦ Check if the indicator lamp lights up.

If not, replace the sensor. ♦ Start the engine and observe the pressure gauge, the indicator lamp should go out at a pressure of 0.3±0.15 bar.

♦ If it doesn't, replace the sensor.

♦ To check the 1.8 Bar sensor, the following operations must be carried out.

♦ Follow the steps above, but instead of turning on the ignition only, start the engine and slowly increase the engine speed.

♦ Check if the pilot lamp lights up at 1.6±2.0 bar.

If not, replace the sensor. ♦ Start the engine and wait until it warms up to operating temperature.

♦ Increase the frequency to 2000 rpm and check if the pressure gauge shows at least 2.0 bar.

♦ If the T4 oil pressure drops below 1.8 bar at 2150 rpm, the oil pump must be repaired or replaced as an assembly.

Oil filter T4 . Tractor MTZ-80 and MTZ-82 - traktor-mtz82.ru