Release bearing replacement

Release bearing Conveyor T4 - ball bearing. On fig. 324 shows the hydraulic clutch release mechanism. If the removed bearing is to be used later, it should not be degreased.

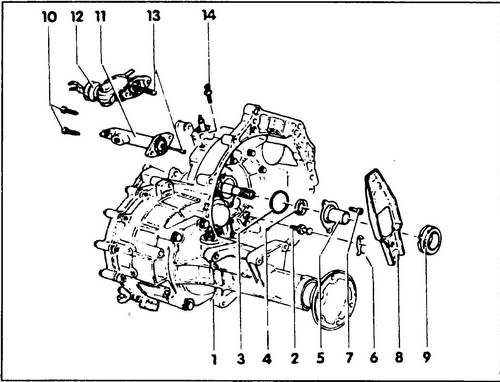

Rice.

324 Clutch release drive device 1 - gearbox, 2 - ball (support) pin, 3 - sealing ring, 4 - input shaft oil seal, 5 - guide sleeve, 6 - spring clips, 7 - bolt, 15 Nm, 8 - release lever clutch, 9 - release bearing, 10 - bolt, 25 Nm, 11 - clutch slave cylinder (hydraulic version), 12 - angle lever (cable version), 13 - rod, 14 - technological stopper

♦ Remove the gearbox.

♦ Release the spring clips and remove the release bearing.

♦ If it is necessary to remove the lever (8), remove it from the ball stud using a screwdriver.

♦ Coat all running and bearing surfaces of the bearing with graphite grease, and then install the T4 release bearing in place.

♦ Secure the bearing with spring clips.

♦ Install the gearbox.

♦ Check the operation of the T4 clutch . Pay special attention to the absence of characteristic noise when switching on individual gears. The noise is especially audible when reverse gear is engaged and indicates that the clutch release mechanism is not working properly.