Clutch cable replacement

Clutch cable The T4 conveyor has a complex design that includes a spring-loaded device to eliminate the gap in the drive.

Before proceeding with the dismantling of the cable, disconnect the device for clearing the gap in the drive. ♦ Fully depress the clutch pedal several times.

♦ Turn the angle lever in the direction “away from the stop”.

This will cause the clearance device in the drive to compress. To fix the device in this position, a service clamp is used at the service station (see Fig. 328, 329), after fixing the device, disconnect the rod from the angle lever. If there is no clamp, secure the device with wire. If the actuator clearance device cannot be compressed, it is damaged. For dismantling, in this case, it is necessary to cut the clutch cable (with a grinder or chisel).

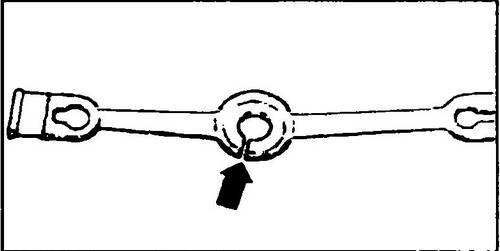

Rice. 328 Service clamp

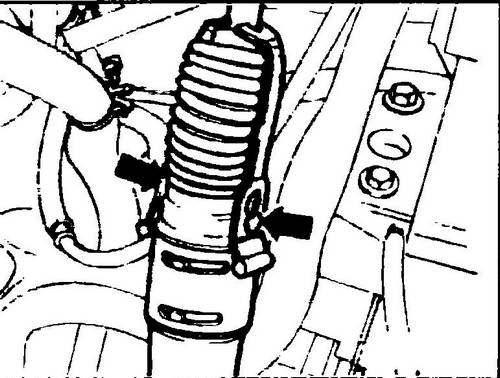

Rice. 329 Fixing the clearance device in the drive

♦ Disconnect the other end of the link from the clutch pedal.

♦ Remove the rubber stop from the bracket at the gearbox.

♦ Pull the rod cover out of the mounting collar.

When installing a new T4 clutch cable, the actuator clearance device must be compressed. First, the cable is attached to the clutch pedal, then the rubber stopper is inserted into the bracket, then the cable is attached to the angled clutch lever, and finally the drive clearance device is released.

In order to install the old cable, proceed as follows:

♦ Attach the cable to the pedal and to the angle lever of the clutch.

♦ The cable sheath must be moved from stop to stop to one side and the other several times, so that the gap eliminator in the drive can come into working position.

When doing this, make sure that the cable does not come loose from the clutch pedal or from the angle lever. ♦ While holding the drive lash eliminator compressed, insert the rubber stop into the bracket.

♦ Fasten the sheath of the T4 clutch .

Check to see if the sheath of the cable is touching the outer transmission control mechanism. ♦ Fully depress the clutch pedal at least five times.

Tilt the crank arm approximately 10 mm in the opposite direction to normal shutdown and check for ease of movement. ♦ Never disassemble the body of the drive clearance device. It contains small parts that can fall out and damage the device.