Measurement of cylinder bore diameters

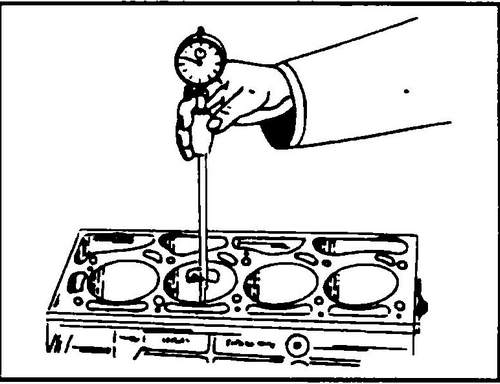

For operation, an indicator inside gauge is required, since only with its help it is possible to accurately measure the diameter of the cylinder Conveyor T4 from above, in the middle and from below (see Fig. 104 and 105).

Rice. 104 Cylinder diameter measurement

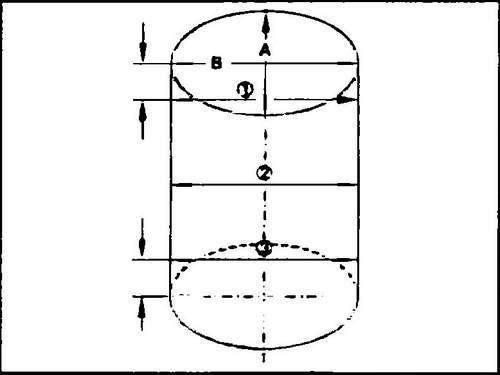

Rice. 105 Scheme for measuring cylinder diameter

Make measurements in the longitudinal and transverse directions at a distance of 10 mm from the upper and lower edges and in the middle of the piston stroke.

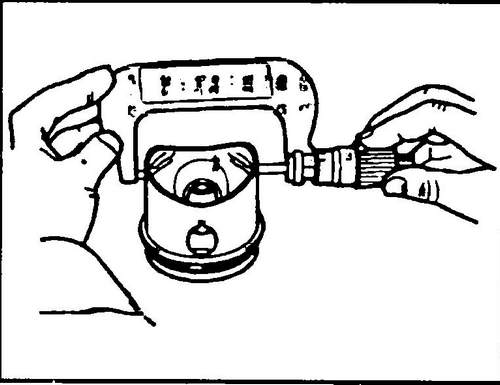

In total, you need to take six measurements for each cylinder. Compare the measured values with the values given in table 1. The maximum deviation from the nominal values is 0.08 mm. Repair dimensions are also collected in this table. If at least one cylinder is worn more than allowed, then all cylinders are reground to the nearest repair size. In this case, all pistons, piston rings, fingers must also be replaced. The size of the cylinder bore is calculated as follows: measure the diameter of the new piston at a distance of 10 mm (VR6 engines - 6 mm) from the lower edge of the skirt in a plane perpendicular to the axis of the piston pin bore (see Fig. 106). Add 0.05 mm piston working clearance to this dimension and subtract 0.02 mm for final honing.

Rice. 106 Measuring the piston diameter

To check the piston clearance in the cylinder, measure the diameters of the pistons and cylinders using the methods described above and calculate the clearance for each individual cylinder. If the values obtained are greater than 0.08 mm, you will have to buy pistons of nominal diameter, since the wear limit of the piston has been reached.

Piston on T4 Transporter. Disassembly of the T4 engine .