Checking pistons and connecting rods

The following measurements must be taken on the Transporter T4 .

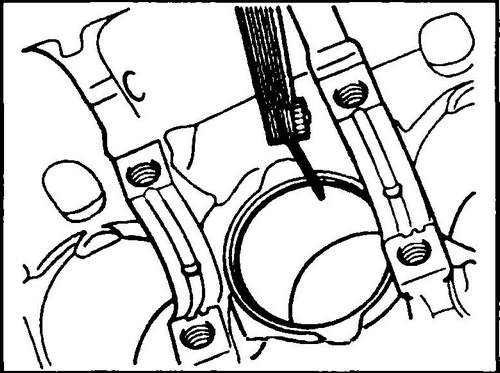

♦ Check the end play of the piston rings in the piston grooves (see fig. 107) using the ring from this groove and a feeler gauge. If you determine that the gap exceeds 0.15 mm, this means that either the ring or its groove is worn. Buy new rings and measure again. If you determine that now the gap exceeds the maximum permissible value, then all pistons must be replaced. The mounting gap of the new rings in the new piston should be in the range of 0.02-0.05 mm.

Rice. 107 Measuring the axial clearance of the piston ring in the piston grooves

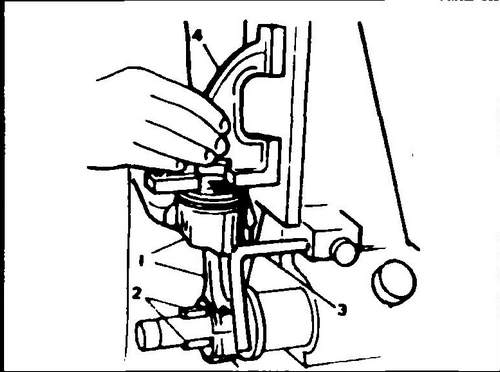

♦ Insert the piston rings one by one into the corresponding cylinder from the crankshaft side.

Move the inserted ring with the inverted piston approximately 15 mm down so that it is perpendicular to the axis of the cylinder. ♦ Measure the ring lock gap with a feeler gauge (see fig. 108). The lock gap of the compression rings should be 0.3-0.45 mm. If the clearance of the lock of the old ring in the working (in diameter) cylinder is greater than the maximum allowable, then the ring must be replaced. The wear limit for all rings is 1.0 mm. For new rings, the lock gap is also subject to measurement. If the gap is less than permissible, then it should be increased by sawing the ends of the ring.

Rice. 108 Measuring the clearance of the piston ring lock in the cylinder

♦ Check the wear of the piston pins and connecting rod bushings.

♦ If at least one of the connecting rods is damaged (bent, damaged surface when turning the bushing, etc.), all connecting rods must be replaced.

♦ Always replace the connecting rod bolt nuts.

♦ Check with a special tool that the connecting rods are not deformed (see fig. 109).

Rice. 109 Checking the connecting rod on a special tool

♦ Check the connecting rod bolts for damage and replace if necessary.

Measuring the clearance between the connecting rod journal and the connecting rod bearing

This operation is described above. Checking this clearance is carried out in the same way as between the main journal and the crankshaft bearing.