Removing pistons and connecting rods

Piston Conveyor T4, together with the connecting rod, is removed from the cylinder towards the head of the block.

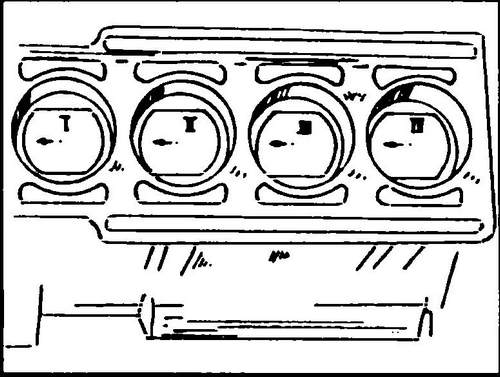

Before this, it is necessary to measure the axial clearance of the connecting rod on the shaft neck. Use a feeler gauge to measure the clearance between the side of the connecting rod bottom head and the bearing surface of the crankshaft journal. The gap should not exceed 0.37 mm, otherwise the connecting rod will wedge on the shaft neck (in this case, the liners have a characteristic “diagonal” wear). If the gap is greater, then the connecting rods or crankshaft, or both, must be replaced. If the gap is normal, it is necessary to dismantle the caps of the lower heads of the connecting rods and the connecting rod half-shells. Each piston T4 and the connecting rod related to it must be marked with the number of the cylinder from which they are removed (Fig. 97, 98).

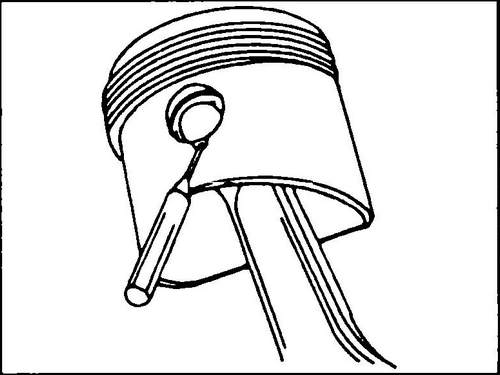

Rice. 97 Piston marking before dismantling

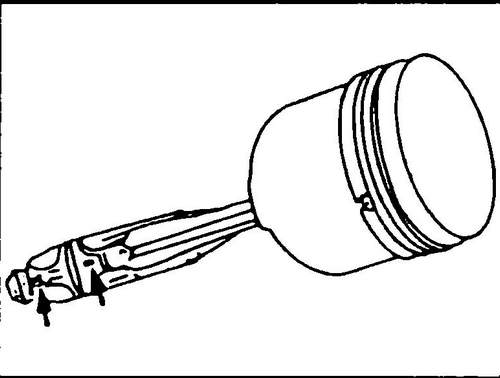

Rice. 98 Marking (see arrow) connecting rod and its cap

♦ Remove the connecting rod cap and bearing, and knock out the piston with the connecting rod with the hammer handle up.

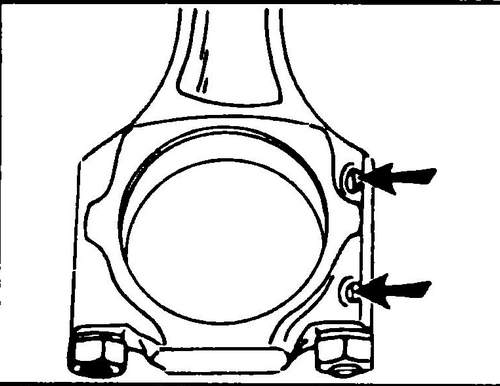

If necessary, use a scraper to remove the shoulder of the unworn part of the liner in the upper part of the cylinder bores. The height of the shoulder can roughly judge the degree of engine wear. ♦ Install the piston with T4 connecting rod in the engine so that both bosses (see fig. 99) point towards the crankshaft belt pulley. Half-liners are marked with nitro paint on the back side in accordance with the number of the connecting rod. You should also mark which one is the top and which one is the bottom.

Rice. 99 Lugs on the connecting rod and its cover on the side of the crankshaft belt pulley

The possibility of reusing old pistons can only be judged after inspecting and checking the block cylinders (see below).

If you need to bore the cylinders to the repair size, then you will no longer need the old pistons. If the cylinders do not have to be bored, then measure the piston diameters (see below) and determine the clearance between the piston and the cylinder.

The next step is to determine the wear of the piston grooves (see below). If the piston is good in both cases (according to the clearance in the cylinder and the clearance of the rings in the grooves), then its further use is possible. In other cases, depending on individual circumstances and the availability of spare parts, either all or only some of the pistons are changed. If the pistons are to be replaced, measure the length of the piston pin immediately after disassembly.

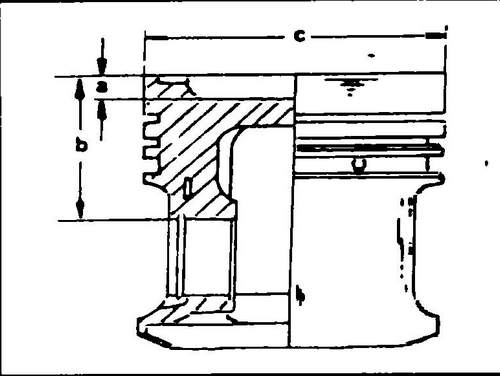

The piston pin is nominally 57 mm long. The new piston must be of the same design. T4 pistons differ in the depth of the combustion chamber in the piston crown (Fig. 100). For example, if you are going to install used pistons, you need to measure the “b” dimension. This is the so-called compression height, which is different for each engine. The new pistons must have the same compression height as the previously installed pistons. There is also a difference in the height of the combustion chamber in piston "a". This height is not the same for all engines.

Rice.

100 Piston arrangement Before replacement, measure dimensions "a" and "b"

The pistons must be disassembled as follows:

♦ Remove the circlips and push out the piston pins. The indentation on the edge of the piston pin bore allows the circlip to be removed as shown in fig. 101.

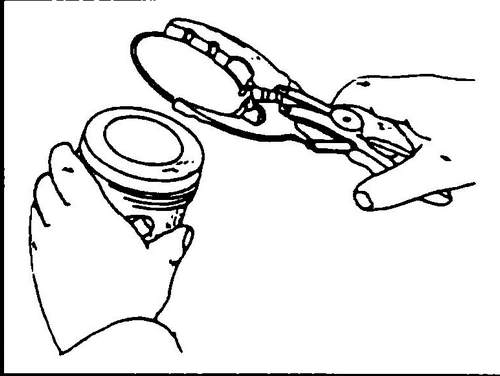

Rice. 101 Removing the circlip from the piston pin

♦ Using the special tool (see fig. 102), remove the piston rings one by one from the side of the piston crown Conveyor T4. If the rings are to be used again, which we would not recommend, they must be marked accordingly. If it is not possible to use a special tool for removing piston rings, they can be removed, as shown in Fig. 103. Insert three metal strips under the rings. Be sure to place one strip under the ends of the ring - this will protect the piston from possible scratches.

Rice. 102 Removing the piston rings with a special tool

Rice. 103 Using flat steel strips to install piston rings