Flywheel - replacement (manual transmission)

The need to replace the T4 flywheel is extremely rare.

Basically, the flywheel is replaced if its flywheel running surfaces are badly worn or damaged. Block the flywheel or crankshaft to loosen the mounting bolts. Coat the threads of the bolts with a locking agent before tightening. The effect of this remedy occurs after 30 minutes, and its hardening lasts from 3 to 24 hours. Thoroughly clean and degrease the affected surfaces before applying the product. If you are installing a new flywheel Transporter T4 , be sure to mark it with the ignition setting;

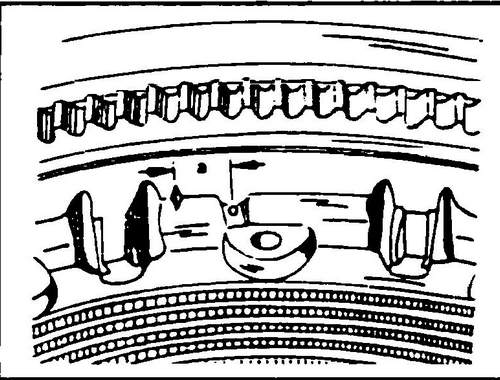

because the new flywheel only has the “0” mark. The mark “0” is not applied on the upper edge of the flywheel, it must be lengthened accordingly. Proceed as follows when marking the ignition: ♦ Locate the “0” mark and mark it on the top edge of the flywheel.

♦ Attach a metal ruler to the teeth of the ring gear;

in the upward direction and from the “0” mark, measure to the left - 14.5 mm. ♦ At the marked place, cut a groove with a file, which will be visible under the strobe light during ignition adjustment (see fig. 119).

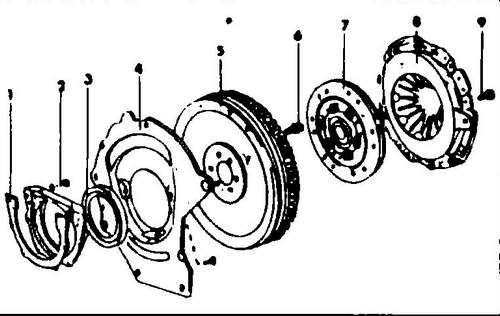

Rice.

118 T4 flywheel and clutch disc 1 - gasket, 2 - bolt, 10 Nm, 3 - oil seal, 4 - intermediate plate, 5 - flywheel, 6 - bolt, 100 Nm, 7 - clutch disc, 8 - clutch cover, 9 - bolt, 20 Nm

Rice. 119 Ignition setting mark on the flywheel