Silent blocks of the lower transverse arm - replacement

Rubber-metal bushings (silent blocks Conveyor T4 ) in both transverse arm bearings can only be replaced with a press (see Fig. 390).

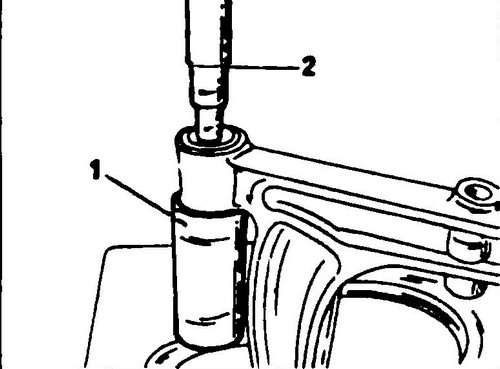

Rice. 390 Installing and removing the silent block of the transverse arm bushing

When replacing, follow the recommendations for also replacing the T4 rear silent block.

♦ Place the lower transverse arm with the front silent block on the piece of pipe and use a rod (2) of the appropriate diameter to push the silent block out of the arm hole. Silent block will fall inside the substituted pipe.

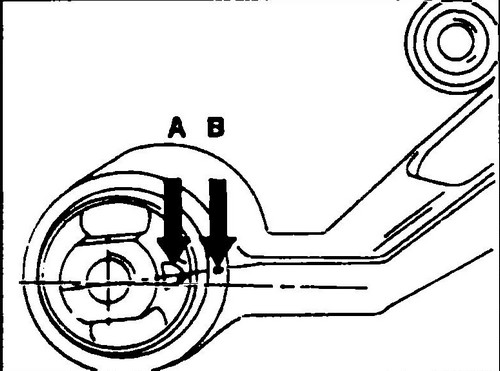

Rice. 391 Correct position of the rear rubber bushing. Sample (A) and mark (B) must lie opposite each other

♦ Moisten the outside of the new bushing with soapy water and push it into the hole in the lever.

Install the lever again on the pipe section and install the bushing with a suitable rod so that its flanges protrude from the lever equally on both sides. Installation should be done very carefully and slowly so as not to install the bushing too deep. When replacing the rubber-metal bushing in the rear arm, it is necessary to additionally maintain the prescribed angular position.

To do this, proceed as follows: ♦ Before removing the old bushing, make a center mark on the lever opposite the "point" of the bushing (see Fig. 391).

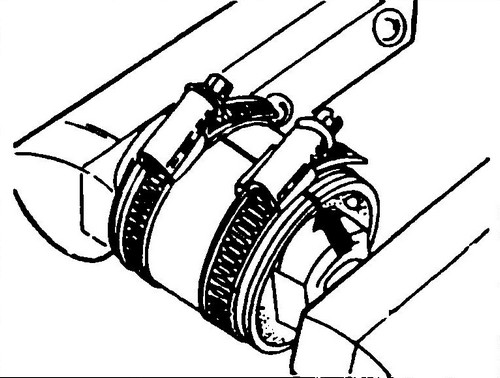

The "point" of the sleeve should be on the line emerging from the axis of the hole on the sleeve and deviated upward by 11º. The angular position of the sleeve is the same on both sides. ♦ Mount the transverse arm on the press as shown in fig. 390 and push out the bushings. A new T4 silent block must first be pre-compressed, since in the free state it has a larger diameter than the diameter of the hole. To do this, install clamping collars at both ends of the T4 silent block and compress them until both outer halves of the sleeve touch (see Fig. 392).

Rice. 392 Installation in the ear of the lever of the rubber-metal bushing

♦ Insert the compressed silent block into the ear of the control arm.

This installation must also be done very carefully. The bushing must be installed so that the distance between the inner surfaces of the front and rear silent block Conveyor T4 must be 371 ± 1.0 mm. This can only be obtained by gradually sinking the sleeve and repeatedly measuring the indicated distance. A correctly installed bushing protrudes slightly on the opposite side.

Be sure to ensure that after installation, the selection in the sleeve is opposite the mark made by the core on the ear of the transverse lever. The sleeve must be properly oriented before installation. The clamping collars put on the silent blocks will be removed by themselves (slip off) during the pressing. When finished, check if the selection (A) (see Fig. 391) is opposite the mark made by the core (B).

structure T4 . Torsion bars conveyor T4.