Replacing the hub and rear wheel bearings

On fig. 406 shows the arrangement and placement of the wheel hub in the trailing arm. The hub and wheel bearing of the T4 Conveyor are held in the arm bore by a long bolt and nut and pressure plate.

To remove and install the hub and wheel bearings, special tools are used, but if necessary, it is possible, for example, the wheel hub, as well as the bearing, to be installed or knocked out with a hammer and a powerful rod. The second possibility is to remove the lever and install the hub and bearings with a press. The following describes repair and replacement using special tools. ♦ Raise the rear of the vehicle and place on stands, remove the rear wheel.

♦ Remove the brake drum.

The drum is attached with only one bolt. ♦ Hold the wheel hub bolt forward and unscrew the nut (6) from the other side.

♦ Remove pressure disc.

Various types of clamping discs are installed. It depends on whether the brake system is equipped with ABS or not. ♦ Pull the wheel hub out of the wheel bearings and arm.

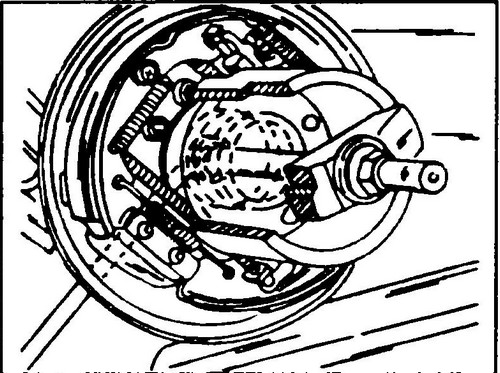

If you want to use a puller for this, it must be of the design shown in fig. 407. Otherwise, you will have to use a rod and a hammer. The rod must be attached to the hub from behind. ♦ Remove the large circlip (11) from the bearing holes in the trailing arm (see Fig. 406).

If a puller is used to remove the bearings, it must be installed as shown in fig. 407, the legs of the puller must be inserted under the outer ring of the bearing. Each time after dismantling, it is necessary to install new bearings.

Rice. 407 Removing the wheel hub or bearing

From the wheel hub, remove the inner race of the bearing, since after removing the hub, this ring remains inside.

To do this, use the puller shown in Fig. 7.20. The puller sleeve must be supported from below so that during operation it does not rest on the springs of the brake shoes

.

To remove it, you need to use a puller. During assembly, install the toothed ring so that its chamfer is directed towards the wheel bearings. ♦ Thoroughly clean all parts of the lever. If necessary, you can remove the brake shield.

Rice. 408 To reinstall the rear lug of the trailing arm in the holes of the arm bracket, loosen the nut (1)

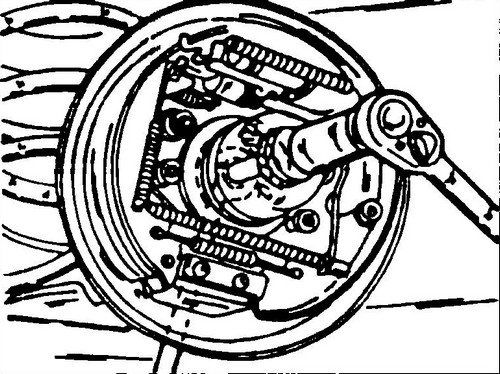

♦ Insert new bearings into the bore of the trailing arm and fit them in place using the special tool (fig. 408). Bearings can also be installed by cutting a pipe of the appropriate diameter. This requires a long bolt that is inserted into the bearing hole from behind through the plate. A piece of pipe is attached to the bearing, a washer of the appropriate diameter is placed on it.

Rice. 409 Installing wheel bearings

A nut is screwed onto the bolt so that it rests on the washer.

After that, it is necessary to tighten the nut until the bearings enter the hole in the lever. ♦ Fit the circlip into the trailing arm bearing bore, making sure that it sits in the groove all the way around.

♦ Then install the wheel hub.

To do this, use the same tools as for installing bearings. ♦ The hub must be pressed in from the outside.

In the case of using a pipe with accessories, the pipe must be installed on the hub and the nut tightened until the hub is fully inserted into the bearings. ♦ Insert a long bolt (4, fig. 406) into the hole in the hub and fit the pressure plate (7) or (14) on the opposite side, depending on the version.

Screw on the nut (6). This is a self-locking nut and must be replaced every time. ♦ After blocking the bolt (4) from rotation, tighten the nut to 200 Nm.

All other work is performed in reverse order.